YAMAHA SMT-Concept „1 STOP SMART SOLUTION“

The Yamaha SMT operation provides “support for the entire factory and the entire process” by providing a wide range of product lines.

To ensure the success of its customers, Yamaha acts as a one-stop shop for solutions to overcome problems on the production line and shop floor through equipment that “does not stop”, “does not produce defective parts” and is “operator independent”.

Responding to customer needs with the high-quality craftsmanship that only YAMAHA can offer

YAMAHA develops and designs high-precision machines, from the world’s fastest pick-and-place machines to high-precision printers and inspection machines. The driving force behind this is the comments of our customers. How can we respond to customer comments? All YAMAHA machines are manufactured with this in mind.

*** Translated with www.DeepL.com/Translator (free version) ***

Continuous, in-depth and comprehensive response to the “wishes” of customers

By combining flexibility and innovative spirit (from i-PULSE) with ultra-fast machines and state-of-the-art assembly quality (from Hitachi High-Tech Group for the Surface Mounter Business), a comprehensive and diverse selection is now available. The establishment of YMRH (Yamaha Motor Robotics Holdings*) is also a step towards becoming a “turn-key supplier” for semiconductor post-processing. The aim is to offer a product range that goes beyond service as a pure solution provider.

By designing and developing machines that meet the requirements of multiple types and variations from all angles, and by providing a system where the customer entrusts all processes from their production facility, Yamaha can not only meet customer expectations, but also create benefits and profits for all parties involved.

History of Yamaha’s SMT business

Yamaha Robotics Co., Ltd (YRC)

Supporting the entire process and the entire factory with the industry’s leading product range

Support through a comprehensive range of “uninterrupted”, “error-free” and “unmanned” production lines and floor concepts. The crucial point in setting up a production line is how to connect the highly specialized machines. One of Yamaha’s specialties is to offer solutions for the production site by combining machines for all processes into a coherent whole.

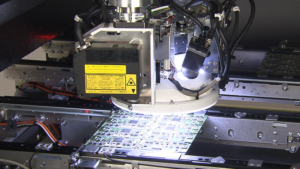

We offer a range of pick and place machines that offer everything from world-leading productivity to maximum flexibility.

Achieving operator-free line support through industry-leading automated part feeding solutions.

Equipping machines with Yamaha technology to continuously meet customer requirements.

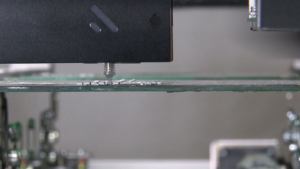

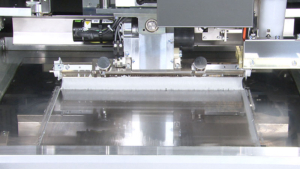

Provision of the high print quality that is essential for SMT processes

Printers that achieve the highest quality regardless of the printing task and have been developed for a wide range of requirements.

Reduction of operational downtimes and realization of operator-free operation through fully automatic setup/changeover, which is a world first.

Inspection machines with outstanding repeat accuracy to ensure SMT process quality

Yamaha is the only manufacturer of pick-and-place machines among the major AOI manufacturers. This is made possible by its expertise in manufacturing robust housings for placement machines and suspensions for motorcycles. The unsurpassed repeatability of Yamaha products contributes significantly to an error-free production line.

Realization of a continuous production line with automated technology

Achieve a line with no interruptions in part feed and no sudden line stoppages.

Achieve the lowest operator stress in the industry and a user-friendly environment for production and craftsmanship.

1 Stop gives “full support”

Realization of a fully automatic set-up/changeover line including the flow from the loader to the unloader

Recipes for fully automatic lines

Achieving high line quality to avoid the occurrence of errors

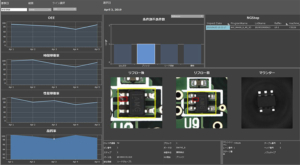

Smart factory “QA option” “N-point adjustment”

Solving problems by coordinating the systems in the factory

Smart factory “M2M-controlled automatic changeovers”

Transparency in production processes through M2M integration systems (machine to machine)

Intelligent factory “Dashboard”