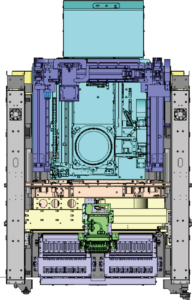

Yamaha i-Cube10 YRH10 hybrid placement machine

The Yamaha i-Cube10 YRH10 hybrid placement machine combines state-of-the-art technology for the mixed assembly of semiconductors and SMDs. This innovative solution from Yamaha ensures maximum precision, efficiency, and flexibility in electronics manufacturing.

Hybrid assembly of semiconductors and SMDs

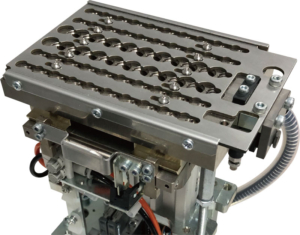

The Yamaha i-Cube10 YRH10 hybrid placement machine enables the combined placement of different components—from semiconductors to SMDs—in a single process. The integrated post-assembly inspection function guarantees consistently high quality.

High-speed and high-precision assembly

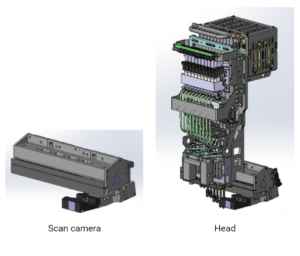

With a 10-nozzle head, the machine achieves an impressive placement rate of up to 10,800 CPH (under optimal conditions) with an accuracy of ±15 μm (Cpk ≥ 1.0).

The inline head with integrated scan camera shortens the distances between pickup and placement, significantly increasing productivity.

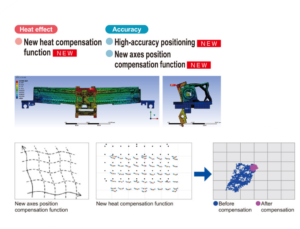

The Multiple Accuracy Compensation System (MACS), developed by Yamaha, compensates for the slightest deviations and ensures consistent precision with every placement.

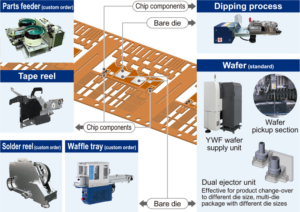

Intelligent feeding for greater efficiency

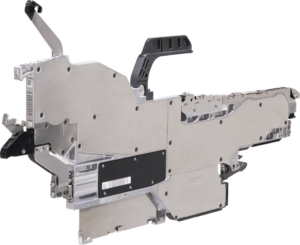

The i-Cube10 YRH10 is compatible with intelligent ZS feeders. These electrical feeding systems increase pick-up accuracy and facilitate handling.

The auto loading feeder allows two rolls to be preloaded, significantly reducing downtime and errors caused by missing components.

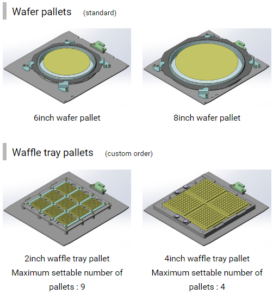

Expandable options

The machine offers numerous options such as nozzle stations for automatic nozzle replacement, blow-off stations, and other customizations.

With its ability to handle large PCBs up to L330 x W250 mm, it covers a wide range of applications.

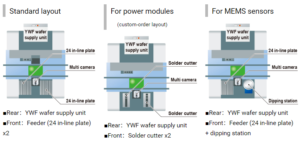

Can be used for various production processes

Adaptable to different production layouts based on product types.

The highly productive, flexible placement machine helps to achieve highly efficient production processes.