YRi-V AOI System – New type of inspection head

The newly developed high-performance probe in the YRi-V AOI system significantly improves the inspection performance of 2D and 3D inspections as well as 4-angle cameras. The inspection service can be used in all SMT areas.

Super high-speed inspections

Yamaha’s proprietary high-rigidity frame enables high-precision and very fast testing. The testing speed is 1.6 to 2.0 times the previous speed, which supports testing in mass production. 56.8 cm²/s (under optimum conditions)

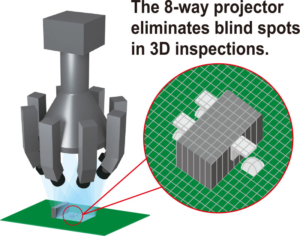

8-fold projector / 4-fold projector

The new 8-way projector enables the inspection of 0201 mm components mounted side by side. The projector reduces the number of blind spots on large components and thus enables high-precision 3D inspections. The extended 3D measuring range enables 3D testing of components with a height of up to 25 mm.

20 megapixel 4-angle cameras

Es wurden hochauflösende 20-Megapixel-Kameras verwendet. Klare Bilder ermöglichen eine genaue sekundäre Beurteilung. Die höhere Bildqualität verbessert die Genauigkeit von automatischen Inspektionen auf der Grundlage von Schrägbildern.

Capable of inspections in the area of devices

New inspection functions have been developed that are required for the inspection process in the component sector. They are able to detect the smallest problems such as cracks and chips on semiconductor components (e.g. wafers and WLCSPs) and thus contribute to improving the quality of components.

Super high-resolution 5μm lenses

The new 5μm lenses enable high-resolution testing compared to the conventional 7μm lenses. The lenses improve performance in the high-precision inspection of very small components (e.g. 0201 mm components) and in the inspection of tiny problems such as cracks and chips on components.

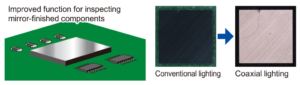

Coaxial lighting mounted

For precise inspection of the surface of highly polished components, the 3-stage white, dome-shaped lighting developed by Yamaha has been supplemented by coaxial lighting. The system, for which the inspection performance required in the component sector has been improved, clearly captures images of the surface of semiconductor components (e.g. wafers and WLCSPs).

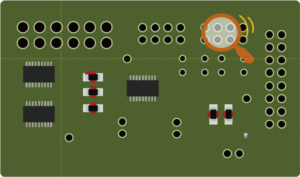

Improved PCB conveyability

YRi-V can process large PCBs with L610mm and W610mm as standard. The two-track system can transport large PCBs with a width of 320 mm on the two tracks.

Two-track system

Das neu entwickelte zweispurige System kann jede Fahrspur flexibel bedienen. Das System, das sich leicht an vor- und nachgelagerte Anlagen anschließen lässt, trägt dazu bei, dass zweispurige Strecken flexibel eingerichtet werden können.

Latest software solution with AI

Es wurden neue, übersichtliche Bedienungsbildschirme mit fortschrittlichem Design eingeführt. Neue Funktionen ermöglichen es, Daten auf einfache Art und Weise zu erstellen.

Mobile judgment and QA option

Bad images are sent to the operator’s mobile unit via a wireless LAN so that a “pass” or “fail” decision can be made remotely. The system also enables operators to make decisions, which helps to save labor.

Automatic creation of inspection data

Das System kann alle Arten von Daten (z. B. CAD-, CAM- und Bestückungsdaten) direkt in Prüfdaten umwandeln und erstellt automatisch Leiterplattenbilder aus Gerberdaten. Das System erkennt automatisch Durchgangsbohrungen auf DIP-Leiterplatten und kann automatisch Prüfdaten erstellen.

Automatic synchronization of the component library [AI function]

AI automatically identifies the part types based on the images captured by the camera and automatically applies the optimal part library, helping to simplify inspection data creation.