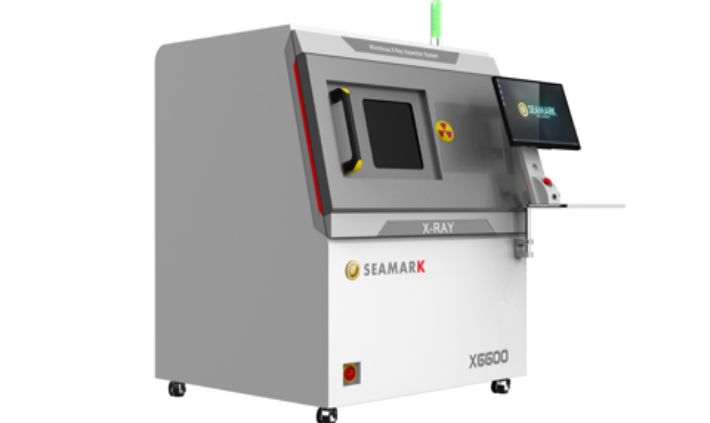

The X6600 offline X-ray machine is a cost-effective, universally applicable offline precision microfocus X-ray inspection device. It is suitable for the inspection of various offline products in the factory. This AXI inspection machine has the features of high magnification, multi-angle inspection and a large-area inspection platform.

Features of the X6600 offline X-ray machine

– Meets the requirements of general industrial X-ray equipment and offers a wide range of applications.

– A high-resolution design can get the best image in a very short time.

– Infrared automatic navigation and positioning, quickly select the recording position.

– CNC detection mode, fast automatic detection for multi-point array.

– Oblique multi-angle inspection makes it easier to detect sample defects.

– The software developed by Seamark is simple and easy to use and has low operating costs.

– The X-ray tube and the FDP can be rotated simultaneously (0-60°), making the detection image clearer and more intuitive.

Specifications of the X6600 offline X-ray machine

Spezifikation der Röntgenstrahlungsquelle

• Type: Sealed microfocus X-ray tube

• Voltage: 90 kV/130 kV

• Operating voltage range: 40-90 kV/130 kV

• Operating current range: 10-200 μA/300 μA

• Maximum output power: 8 W/39 W

• Microfocus spot size: 5-15 μm

Flat screen detector specification

• Type: TFT industrial dynamic FPD

• Pixel matrix: 1536×1536

• Field of view: 130mm×130mm

• Resolution: 5.8Lp/mm

• Image: (1×1) 20fps

• A/D conversion bit: 16bits

Size: L1360mm×W1240mm×H1700mm

Input power: 220V 10A/110V 15A 50-60Hz

Maximum sample size: 540 mm×440mm

Control: Industrial PC WIN7/ WIN10 64bits

Net weight: approx. 1170KG

Radiation:<1μSv/h

Max tilt angle: 65 degrees