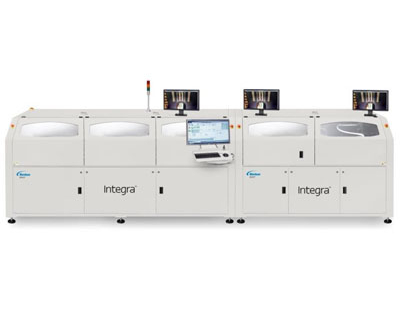

The SELECT Synchro™ 5 uses breakthrough synchronous motion technology to dramatically reduce conveying time and increase throughput by 20-40% for most applications. Single-sided, double-sided through-hole, mixed-technology surface mount and through-hole assemblies run uninterrupted through the system for outstanding productivity.

Overview

Continuous selective soldering delivers results

Process up to seven PCBs simultaneously with different alloys and nozzles or one fixed nozzle for all your products. The Synchro 5 system features microdroplet jet flux and can accommodate up to five solder nozzles for applying lead-free and lead-containing alloys.

The SELECT Synchro 5:

– Quick. Reduces transport time to increase throughput by 20-40% for most applications. With comparable transport and soldering times, a greater gain is possible.

– Easy to use. Automatically balances soldering work between solder pots to increase throughput.

– Compact. Reduces system footprint by 60% compared to conventional multi-station soldering machines.

– Flexible. Supports five solder pots, each accommodating different nozzle sizes, eliminating the need to change nozzles.

– Reliable. Forms reliable solder joints without overheating adjacent components to protect product performance.

Select a system package:

– Indispensable – The standard Synchro 5 system provides uninterrupted selective solder productivity for 460 mm x 2500 mm boards.

– Large format – The Synchro 5 XL system provides uninterrupted selective solder productivity for 680 mm x 2500 mm boards.

The basic model includes:

– Five solder pots.

– Independent areas for simultaneous fluxing, preheating and soldering.

– SMEMA compatible with positive board position.

– Automatic adjustment of the conveyor belt width.

– MicroDrop jet fluxer.

– Acquisition of the level of the river.

– Full titanium solder pot and pump assembly.

– Magnetically coupled quick-change soldering nozzle.

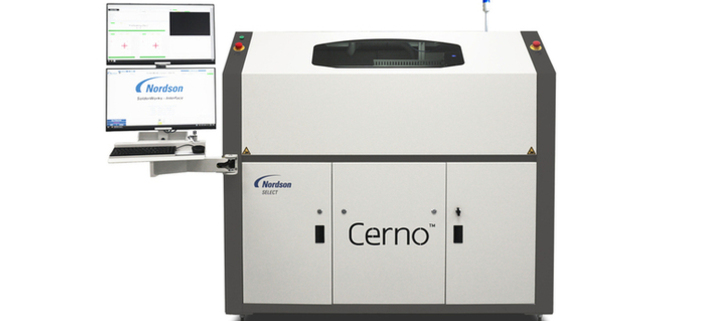

– SolderWorks Editor software for easy point-and-click programming.