High-speed Dispenser YRM-D System – Höchste Geschwindigkeit und Präzision für moderne SMT-Linien

The High-speed Dispenser YRM-D system is a high-performance solution for high-precision and flexible dispensing processes in electronics production. It enables fast, stable and extremely precise liquid applications on a wide variety of PCBs. As a result, the system increases productivity and reliably supports high-density and complex PCB layouts.

High-speed Dispenser YRM-D System – Fast and precise dispensing

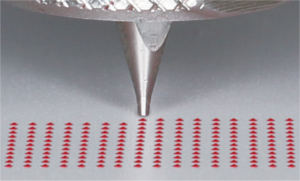

The system achieves a very high dosing speed while maintaining maximum accuracy. This combination ensures stable production processes with maximum output.

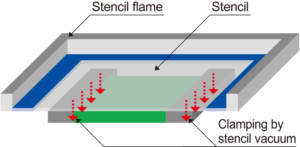

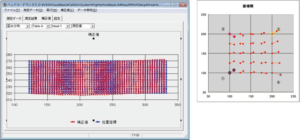

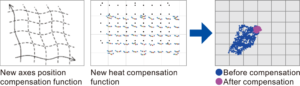

The High-speed Dispenser YRM-D system recognizes several reference marks on the PCB and corrects the position locally. As a result, dispensing remains precise, even with PCBs that tend to warp, expand or contract.

Fiducial correction on the entire circuit board

The position is automatically corrected for large-format or imprecise PCBs. This ensures that the dispensing quality remains constant.

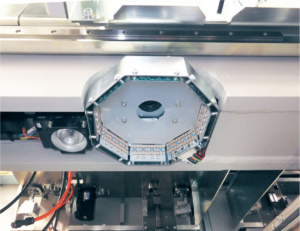

Local brand recognition for maximum accuracy

Individual local marks enable high-precision work even on challenging materials such as paper phenol PCBs.

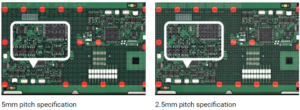

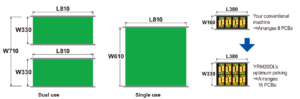

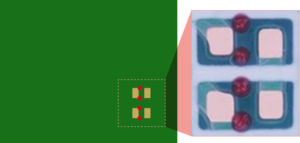

Flexible application options for different PCB types

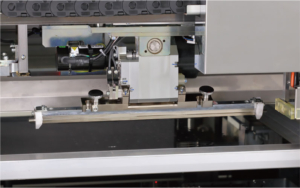

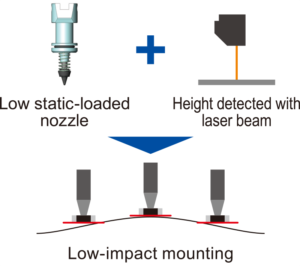

The system is particularly suitable for complex high-density PCBs. Unevenness or depressions are no problem, as the surface is measured by laser. The height information obtained is transferred directly to the dispensing height. This reliably prevents errors such as contact damage.

The system is also suitable for a wide range of liquids and is compatible with many common syringes from 5 to 30 cc. This means less work for accessories and storage.

Reliable control of expiry dates

The system documents the removal and return of dispensing materials. This means that expiry dates can be traced at any time and old materials can be reliably excluded.

Efficient automation for less work

Several functions support a significant reduction in manual activities:

-

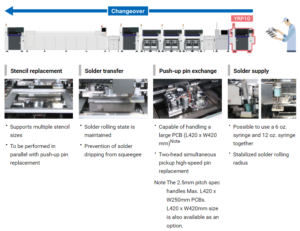

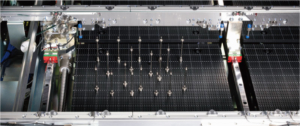

Automatic change of push-up pins reduces set-up times.

-

Automatic data generation converts CAD data into dosing data.

-

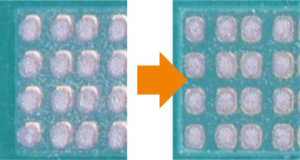

Pre-dosing recognizes the droplet diameter and automatically regulates the dosing quantity.

-

Fill level sensors report in good time when the syringe is almost empty.

-

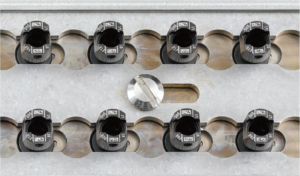

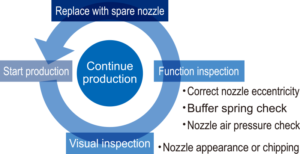

Direct mounting of the nozzle facilitates cleaning and maintenance.

This automation increases process stability and significantly reduces preparation times.

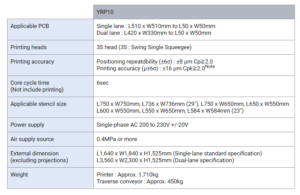

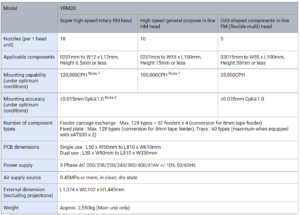

Technical data – High-speed Dispenser YRM-D System

-

Dosing method: Air-pulsed

-

Dosing performance: 0.07 s/shot (grade 1)

-

Dosing accuracy: ±0.05 mm, Cpk ≥ 1.0

-

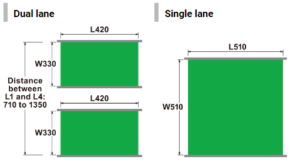

PCB size: L50 × W50 mm to L510 × W460 mm

-

Power supply: 3-phase AC 200-416 V ±10 %, 50/60 Hz

-

Air supply: ≥ 0.45 MPa, dry and clean

-

Dimensions: L1,254 × W1,440 × H1,445 mm

-

Gewicht: ca. 1.200 kg

- Laserklasse: Class 1 Laser Product (IEC60825-1, FDA Part 1040.10)