High-speed, high-quality printer that enables fully automatic settings and changeovers.

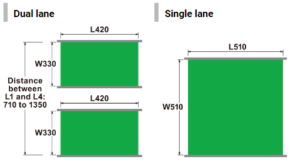

It supports both single-lane and dual-lane production.

- High-speed printing performance Core cycle time: 6 seconds

- Pressure accuracy μ±6σ : ±16μm Cpk≧2.0

(Measured with CeTaQ under optimal conditions by YAMAHA) - Fully automated set-up and retooling

- Two-track, fully independent production

Delivers both high quality and super-precise printing!

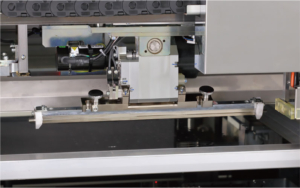

YAMAHA’s original 3S head

Programme the angle of attack and the speed of the squeegee to an ideal setting in order to create optimum printing conditions that correspond to the solder used.

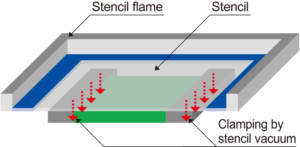

Stencil vacuum

A stencil vacuum mechanism ensures consistently high-precision printing without the effects of stencil sagging. In addition, the set-up time is drastically reduced as no offset input is required during the back and forth movement of the print.

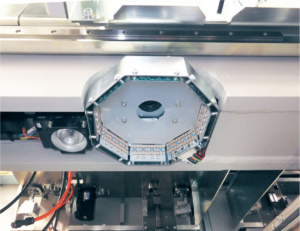

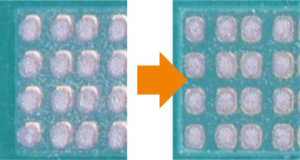

Integrated inspection camera of the printer

Supports professional-level inspections with a special camera. The feedback of the test results enables overprinting and stencil cleaning.

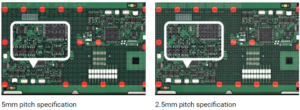

Push-up pins for high-density PCBs

Up to 200 pins can be arranged. In addition to a grid plate in a 5 mm grid, a grid plate in a 2.5 mm grid with a higher degree of arrangement freedom is also available as an option.

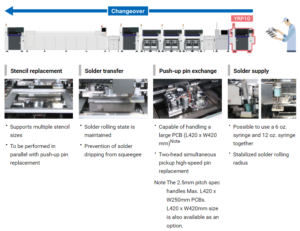

Fully automatic set-up and changeover & longer non-stop operation

Ultra-highly efficient support for a wide range of production models

Automatic replacement of the template and push-up pins. The combination with automatic changeovers throughout the line has drastically reduced labour hours and the number of human errors during model changeovers. The non-stop solder supply with a 12-ounce syringe enables longer, unmanned non-stop solder printing.

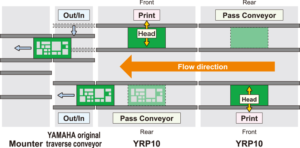

Two-track, fully independent production

Flexible double track

Connecting two YRP10s in series enables fully independent two-track operation. Two-track operation and an automatic switching function are supported simultaneously. An additional traverse conveyor flexibly connects the YRP10s to the downstream systems.

B330 dual carriageway

Large PCBs with a size of up to L420 × W330 mm can be produced on a double track. You can increase the number of PCBs to be taken and the number of PCBs to be transported from the carrier, which increases production efficiency.

M2M link solution

Feedback of the inspection result

It is possible to clean the template and correct its position based on the feedback of the inspection results via the connection to the SPI.

Analysis of the solder paste pressure

Indicates the relationship between variations in solder size and solder paste print status and allows the solder paste printer status to be checked if defects or problems occur. Rationalise the quality improvement and operating rate of the line.

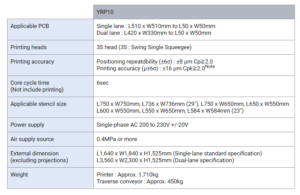

Specifications