Single In-Line Router iDPL-S – precision, efficiency and intelligent process control

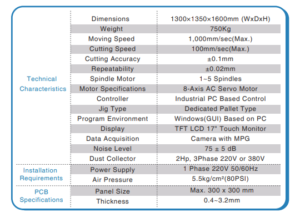

The iDPL-S single in-line router combines high speed, precision and compact design in a modern in-line system.

With its double-spindle technology, dual transfer mechanism and intelligent real-time monitoring, it is designed for maximum productivity and stable process quality.

The system was specially developed for electronics production that requires short cycle times, high accuracy and minimal downtimes.

Fastest cycle time thanks to dual-spindle system

The Single In-Line Router iDPL-S works with two high-performance spindles that can be used independently or in parallel.

This configuration drastically reduces the cycle time and enables several PCB segments to be routed simultaneously.

The precise control ensures clean cutting edges, minimal burrs and consistent quality, even with complex PCB layouts.

Dual transmission for maximum efficiency

The dual transfer system minimizes idle times through simultaneous loading and unloading.

While one PCB is being processed, the next one can already be positioned – a decisive advantage for series production with high throughput.

The router offers a choice of vacuum or gripper unloading in order to adapt optimally to different PCB sizes and shapes.

Real-time monitoring and process reliability

An integrated monitoring system analyzes the spindle speed in real time and automatically detects bit breakage or slippage.

Together with the automatic bit position correction, this ensures consistently precise cutting results and maximum process stability – even in continuous operation.

All machine parameters are monitored and displayed via the GUI, giving the operator full control of the process at all times.

User-friendly control and simple programming

It is controlled via a user-friendly GUI based on IPC standards and visualized on a touch LCD display.

Thanks to camera and MPG/jog support, programming is quick and intuitive.

New product models can be set up in a very short time, and the fast model changeover makes the router particularly flexible for changing production requirements.

Compact design and high flexibility

With its compact footprint, the iDPL-S can be easily integrated into existing inline production lines.

Its robust structure minimizes vibrations and ensures precise results over long operating times – with low maintenance requirements.

Optional extensions

-

Fingerprint verification & protocol management for secure operator identification

-

Teaching data conversion (CAD/CAM) for direct program transfer

-

Tower Light & network module for LMS integration and machine status monitoring

-

Image processing system for detecting fiducial marks, barcodes and NG markings

-

Barcode interlocking & MES interface for production traceability

-

Pass/fail PCB separation for automatic quality selection

-

Pallet transport system or shuttle solution for flexible material supply

-

Edge detection for perfect cutting accuracy

-

Automatic filing function for optimized process integration

-

Real-time self-diagnosis of the dust extractor for uninterrupted operation

Advantages at a glance

-

Dual-spindle technology for maximum speed and precision

-

Dual transfer system to minimize idle times

-

Real-time monitoring of spindle speed and tool conditions

-

Automatic bit position correction for perfect milling depth

-

Camera-supported programming & touch GUI for easy operation

-

Vacuum or gripper unloading for flexible handling

-

Compact design with quick model changeover

The iDPL-S single in-line router combines the latest milling technology with intelligent control and ease of use – perfect for electronics manufacturing companies that want to combine productivity, precision and process reliability in one compact system.

To the other products ->