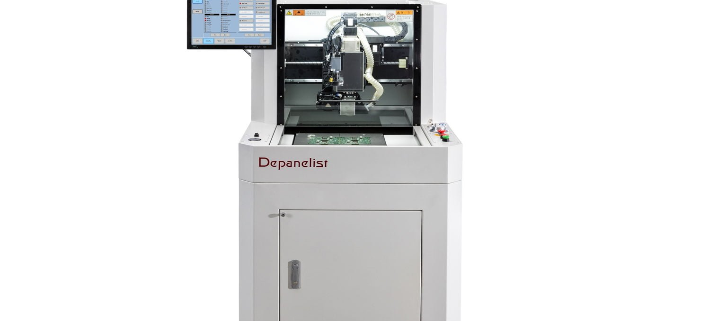

Double in-line router

Properties

• Double table inline router for high C/T and versatility

• With double spindle as standard

• Dual transmission for minimum idle time

• Highly efficient dust collection system for 0% residual dust

• Quick and easy programming with camera and MPG/Jog

• User-friendly GUI based on IPC & Touch LCD

• Compact design

Options

• Barcode interlocking & MES interface

• Pallet transport system

• Auto Tray System

• ID verification with fingerprint

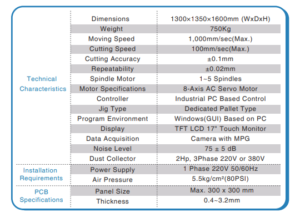

Technical details

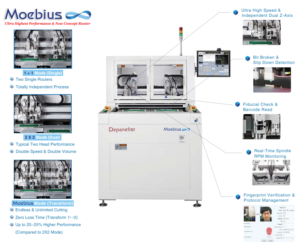

Ultimate PCB-Depaneling-Router. Routing for 2 types of PCB in one machine!

Advantages

• “NEW CONCEPT” Endless & Unlimited cutting

• Loss-free time (Transform 1-2)

• Ultra-high speed and independent double Z-axis

• Selective use of single or double spindles

• The shortest cycle time of Dual Spindle

• ioniser for easy dust removal

• User-friendly GUI based on IPC & Touch LCD

• Quick and easy programming with camera and MPG

• Bit Broken & Slip Down Detection

• Automatic bit position correction

• Monitoring the spindle speed in real time

• Fast model changeover

• Safety interlock to protect the operator

• Automatic loading and unloading system

Options

• Fingerprint verification and log management

• Teaching data conversion (CAD/CAM)

• Tower Light network module for LMS or machine status monitoring

• Vision system for fiducial and barcode reading

• Barcode interlocking & MES interface

• Edge detection for perfect accuracy

• Real-time self-diagnostic dust separator

• Automatic tray 1 pallet unloading system

• NG separation

• Pass / Fail PCB Automatic disconnection

• Conveyor belt (standard) / Tray (option) / Pallet (option) Unloading system

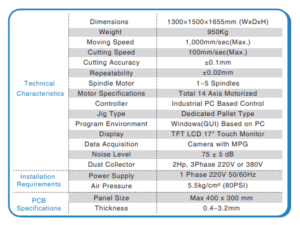

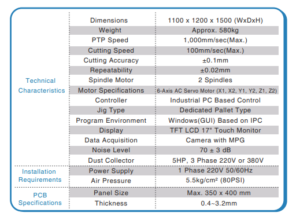

Technical details

Undercut In-Line Router

Properties

• Tiller for soil cultivation

• Template – Less with gripper type

• Highly efficient dust collection system for 0% residual dust

• User-friendly GUI based on IPC & Touch LCD

• Compact design

Options

• Barcode interlocking & MES interface

• Pallet transfer system

• OK/NG PCB separation

• ID verification with fingerprint

Technical details

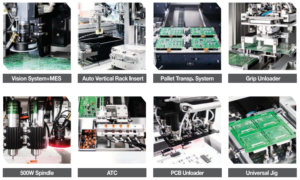

Ultra high-speed inline router with iDPL-ST automatic filing system

Properties and advantages

• Automatic filing function

• Fastest cycle time thanks to new crank-controlled Z-axis

• Larger spindle pitch (min. 40 mm)

• Monitoring the spindle speed in real time

• Shuttle type In-Let conveyor (free lay-out)

• Pass/Fail PCB separation

• Selective use of single or double spindle

• Programme-free loading and unloading position

• Detection of broken bits and slipping

• Two touch monitors

• Compact footprint

• Fast model changeover

Options

• Fingerprint verification and protocol management

• Teaching data conversion (CAD/CAM)

• Tower Light network module for LMS or

monitoring the machine status

• Automatic loading/unloading of compartments with AGV system

• Barcode interlocking & MES interface

• Real-time self-diagnosis dust separator

Outstanding properties

Specifications

Double off-line router

Properties

• Double table offline router

• Double spindle as standard

• Highly efficient dust collection system for 0% residual dust

• Quick and easy programming with camera and MPG/Jog

• Benutzerfreundliche GUI auf Basis von IPC und Touch-LCD

• Compact design

Options

• Image processing system

• Barcode interlocking & MES interface

• Bit recognition system

• ID verification with fingerprint

Technical details

Routing for 2 types of PCB in one machine!

Properties and advantages

• “NEW CONCEPT” Endless and unlimited cutting

• Zero loss time (Transform 1↔2)

• Ultra-high speed & independent double Z-axis

• Selective use of single or double spindle

• Shortest cycle time due to double spindle

• Compact footprint

• Ioniser for easy dust removal

• Benutzerfreundliche GUI auf Basis von IPC und Touch-LCD

• Quick and easy programming with camera and MPG

• Automatic bit position correction

• Fast model changeover

• Safety sensors to protect the operator

Options

• Fingerprint verification and protocol management

• Teaching data conversion (CAD/CAM)

• Tower Light network module for LMS or

monitoring the machine status

• Image processing system for fiducial and barcode reading,

NG brand recognition

• Barcode interlocking & MES interface

• Edge detection for perfect accuracy

• Bit breakage and slip detection

• Real-time monitoring of the spindle speed

• Real-time self-diagnosis dust separator

Specifications

Double PCB saw system

Properties

• Double table PCB sawing system

• X & Y full-duplex cutting (rotating saw head)

• Simultaneous dust extraction top/bottom

• Quick and easy programming with camera and MPG/Jog

• User-friendly GUI based on IPC & touch LCD

• Compact design

Options

• Image processing system

• Barcode interlocking & MES interface

• Bit recognition system

• ID verification with fingerprint

Technical details

Single PCB sawing system

Properties

• Single table PCB sawing system (off-line)

• X & Y full-duplex cutting (rotating saw head)

• Simultaneous dust extraction top/bottom

• Quick and easy programming with camera and MPG/Jog

• User-friendly GUI based on IPC & touch LCD

• Compact design

Options

• Image processing system

• Barcode interlocking & MES interface

• Bit recognition system

• ID verification with fingerprint

Technical details

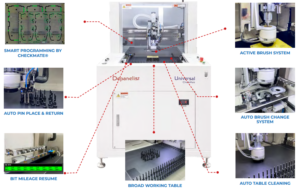

Multi-board assembly on the worktable at the same time

Properties and advantages

• Universal-Router powered by Checkmate®

• Automatic pin placement and return with

robust magnetic pins

• Intelligent programming through image scan, edges

Detection and off-line programming

• Active brush system for dust-free working

• Automatic brush changing system (ABC)

• Automatic tool changing system (ATC)

• Total Tool Management with Bit Mileage

Resumption

• Automatic bit diameter detection

• Automatic detection of the bit ring colour (for ATC)

• Automatic table cleaning

• Multi-loading up to four panels

• No tool costs, cost savings

• Self-diagnosis of the spindle speed in real time

• Inspection of cutting accuracy (optional)

Options

• Edge detection and inspection

• Barcode interlocking & MES

• DXF/Gerber conversion

• Bit diameter detection

Outstanding features

Technical details

Informationen

Über uns

Kontakt

neutec electronic ag

Gheidstrasse 5

CH-5507 Mellingen

Tel: +41 44 948 17 11

Fax: +41 44 948 17 37

Mail: info@neutec.ch