European manufacturers of automotive lighting are leaving traditional electrical production processes behind and becoming high-speed manufacturers of precision electronics

In recent years, the LED lighting revolution has changed both vehicle design and the quality of road illumination. At the front and rear of vehicles, the change is reflected in new designs, new shapes and distinctive branding. The cars are illuminated more brightly and are clearly visible at any time of day or night. The brighter, whiter headlights highlight the course of the road more intensively. In the interior, the revolution is reflected in improvements such as the customizable lighting atmosphere, which allows occupants to determine their own desired sense of space.

The switch to LED lighting is also leading to changes in the manufacturing processes for these “light generators”. A large number of individual LEDs can be arranged in grid structures or strips. This also requires associated power supply and control circuits. The required components are placed on rigid or flexible printed circuit boards using surface mounting technology. It is a huge change compared to conventional techniques, in which the production of lamp units is transformed into a high-precision process chain that can only be managed with the help of specialized automation technology.

Yamaha Robotics SMT Section is a leading supplier of surface mount equipment chosen by renowned OEMs and EMS companies for the production of LED lighting assemblies for the automotive industry. Yamaha’s customer base ranges from multinational Tier 1 companies to new market entrants with innovative concepts.

Working directly with customers in this industry and through its network of distributors and dealers across Europe, Yamaha has supplied complete surface mount lines for lighting and general electronic assemblies for the automotive industry. These include electronic control units, power modules, sensor modules, chargers and inverters for hybrid and electric vehicles.

All automotive assemblies must be manufactured to specific, high standards. Automotive manufacturers typically apply their own quality specifications to evaluate the components and subsystems supplied by their suppliers. To be successful in this market, one must commit to delivering large quantities according to tight schedules required to keep the automotive assembly lines running.

Many of the companies now taking on the challenges of manufacturing LED assemblies have many years of experience as automotive suppliers and have been manufacturing conventional lighting products for many years. Some of them have in-house optical, potting, mechanical and electrical/electronic design facilities and are enhancing and expanding these capabilities with new tools such as computer-aided lighting software, modeling and simulation, including thermal performance and hue analysis.

On the other hand, many are taking their first steps in the surface mounting of electronic assemblies. “Our customers are looking for automated inline systems that are capable of placing components at high throughput rates in the shortest possible time. They demand fast product changeovers, minimal line interruptions and support for traceability, which is a must in the automotive industry,” comments Shuichi Imai, SMT Sales General Manager at Yamaha Robotics.

1 STOP SMART SOLUTION

The Yamaha 1 STOP SMART SOLUTION brings all these capabilities together in a portfolio of stencil printing, part assembly and automatic optical inspection (AOI) platforms that communicate closely to ensure uninterrupted production with comprehensive diagnostics and reporting capabilities. Operators are kept continuously informed in real time of the current status and progress towards production targets. Each of these machines can also be supplied individually to upgrade slower or less highly automated equipment from other manufacturers. The YRi-V 3D AOI machine can even be used as a standalone system with automatic program generation using Yamaha’s YSUP software to reduce the time to market for new products.

“Sometimes prospective or customer teams come to us knowing exactly what production capabilities, speeds and features they need, while others need more advice and assistance,” explains Shuichi Imai. “Of course, we have a lot of experience in general SMT assembly, LED-specific know-how and in-depth knowledge of the requirements of the automotive sector in order to offer the right advice in each case.

As part of the 1 STOP SMART SOLUTION, theYRP10 stencil printer impresses with its excellent repeat accuracy and high level of user-friendliness. Its features include a standard cycle time of just five seconds and the 3S print head (Swing Single-Squeegee), which automatically optimizes itself when the solder paste roll gets smaller. Automatic stencil loading and set-up effectively reduces the time between job changes to zero, so the next job can start immediately.

YRP10 from Yamaha

The YRM20 pick and place machine can place components at a placement rate of up to115,000 CPH. They process a wide range of components from 0201 (mm) with the multi-purpose head option, which ensures high speed and versatility as well as minimal changeover times. The lateral component detection determines the pick-up status without delay and the placer automatically generates detection data for customer-specific or other unusual components.

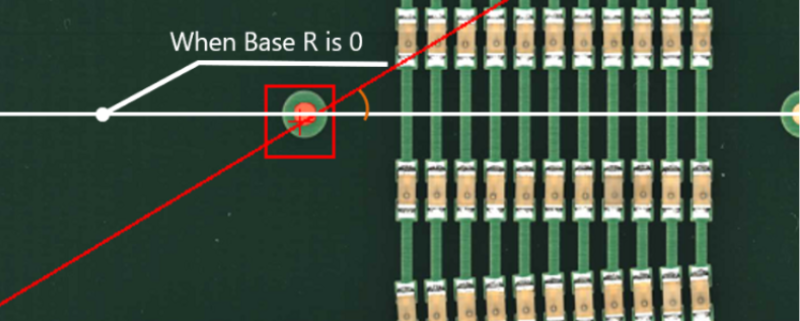

The YRi-V AOI system combines powerful image processing with high-quality optics and high camera resolution. The illumination offers multiple light angles and wavelengths as well as laser height measurement to verify correct component placement and solder joint integrity. The YRi-V delivers reliable results in a short cycle time, enabling consistently accurate quality control even at high production throughput. In early 2024, Yamaha introduced a new multi-part alignment check feature for the YRi-V machine, which is ideal for LED array assembly. The time and complexity previously associated with programming the machine to check the correct positioning of large LED arrays is significantly reduced.

Checking the multi-component alignment ensures precise LED alignment

All machines are designed for quick product changeover. This enables lighting manufacturers to produce a wide variety of products and expand their customer base among those automotive manufacturers looking for the best ways to produce advanced lighting for their new vehicle models.

Shuichi Imai summarizes: “Our 1 STOP SMART SOLUTION meets all requirements for surface mounting and inspection of components. At the same time, it is highly flexible and can be configured to meet the requirements of a wide range of customers. In collaboration with our sales partners, we offer customized solutions that help companies successfully enter the world of automated and highly productive high-speed electronics assembly.”

About Yamaha Robotics SMT Division

The Yamaha Surface Mount Technology (SMT) Section, a subdivision of the Yamaha Motor Robotics Business Unit of Yamaha Motor Corporation, produces a comprehensive range of systems for high-speed in-line electronics assembly. This 1 STOP SMART SOLUTION includes solder paste printers, pick and place machines, 3D solder paste inspection machines, 3D assembly inspection machines, flip-chip hybrid pick and place machines, dispensers and management software.

Bringing the Yamaha approach to electronics manufacturing, these systems emphasize intuitive operator guidance, efficient coordination between all in-line processes and modularity that enables users to meet the latest manufacturing requirements. The Group’s expertise in controlling servo motors and camera-based image processing systems ensures maximum precision at high speed.

The current product line includes the latest generation of YR machines with advanced automation features for programming, set-up and changeover, as well as the new YSUP management software with state-of-the-art graphics and integrated data analysis.

By combining expertise in design and engineering, manufacturing, sales and service, the Yamaha SMT Section ensures operational efficiency and easy support access for customers and partners. With regional offices in Japan, China, South East Asia, Europe and North America, the company offers a truly global presence.

http://www.yamaha-motor-robotics.de/