Neutec electronic ag becomes exclusive distributor of Seamark X-Ray inspection solutions for the Swiss market

neutec electronic ag, a leading company in the field of electronics and automation technology, is proud to announce its exclusive partnership as a distributor for Seamark X-Ray inspection solutions on the Swiss market. This pioneering cooperation enables neutec electronic ag to offer its customers in Switzerland first-class X-ray inspection solutions that are characterized by Seamark’s many years of experience and quality.

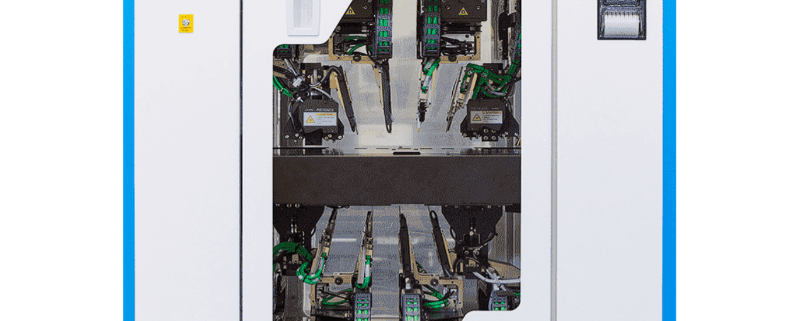

The agreement between neutec electronic ag and Seamark X-Ray enables Neutec to distribute Seamark’s complete product portfolio of state-of-the-art X-ray inspection solutions to the Swiss market. These solutions are widely used in various industries, from production to quality control, and offer innovative technologies for precise and reliable inspection, inventory management and component management.

Mr. Gianni Affinito, Managing Director of neutec electronic ag, commented on this partnership:

“We are very pleased about the exclusive partnership with Seamark X-Ray as a distributor on the Swiss market. Seamark’s innovative inspection solutions are groundbreaking in terms of precision and efficiency. This cooperation enables us to provide our customers in Switzerland with state-of-the-art technology and meet their needs in the field of X-ray inspection in various industries. This partnership will enable us to make X-ray technology available to the masses in Switzerland”

Seamark X-Ray is internationally recognized for its high quality inspection solutions, which are valued in the industry for their precision and reliability. The exclusive partnership with neutec electronic ag strengthens Seamark’s presence in the Swiss market and offers customers in the region direct access to first-class X-ray inspection solutions.

The exclusive partnership between neutec electronic ag and Seamark X-Ray comes into effect immediately. Both companies are convinced that this cooperation will help to meet the requirements for X-ray inspection solutions in Switzerland and strengthen the competitiveness of the domestic industry.

About Seamark X-Ray: Seamark X-Ray is a renowned provider of X-ray inspection solutions with a wide range of applications in various industries. The company is characterized by its industry-specific expertise and its commitment to excellence.