Yamaha Robotics presents award-winning dual-track pick-and-place machine and new software at Productronica 2023

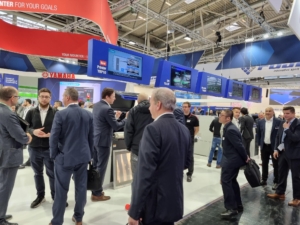

At Productronica 2023, Yamaha Robotics presented the YRM20DL dual-lane pick and place machine for the first time in Europe and also unveiled new features of its powerful Smart Factory software tools.

Yamaha presented the YRM20DL together with the latest 1 STOP SMART SOLUTION machines and accepted the Global Technology Award for the advanced new machine at a ceremony on the stand on the first evening of the event. The YRM20DL is the first dual-lane pick and place machine that offers the full flexibility to pick and place high-volume and high-mix jobs on the same platform. It can be efficiently combined with Yamaha’s YRP10DL dual-track printer and the YRi-V DL dual-track 3D AOI system.

The Yamaha team celebrated winning the Global Technology Awards in the Pick-and-Place High-Volume category

“Productronica 2023 was a great success for Yamaha with the European premiere of the YRM20DL and our great win of a Global Technology Award in the High-Volume Pick-and-Place category,” said Daisuke Yoshihara, General Sales Manager. “We welcomed numerous visitors, many of our Yamaha customers as well as new interested parties who wanted to find out about the latest innovations of our 1 STOP SMART SOLUTION and the latest intelligent software tools.”

Yamaha welcomed a large number of visitors every day at Productronica 2023

Yamaha’s Product Manager Kamil Stasiak presented the new Smart Factory tools in a special software area at the trade fair stand and in a special presentation at the Productronica Forum. The YSUP dashboard, now with automatic analysis, immediately identifies the causes of pick-up errors and inspection errors, so that the system is now independent of the assessments of individual operators. Other new functions analyse and verify both component placement and print results.

Kamil Stasiak presents at the Productronica 2023 forum

The 1 STOP SMART SOLUTION presented at Productronica includes Yamaha’s latest YR series machines, which offer maximum precision and stability as well as the latest functions for even greater speed and efficiency. The YRP10 premium printer automates previously labour-intensive processes such as stencil changes and solder paste transfer, while the YRM20 pick and place machine enables continuous feeder carriage and feeder changes. The YRi-V 3D AOI system combines high-resolution image processing with high-speed graphics processing, which has now been enhanced with AI to improve component recognition, simplify programming, minimise cycle time and increase inspection accuracy.

Visitors to Productronica were also able to see Yamaha’s industrial robots in action. They demonstrated their ability to carry out general assembly, picking, placing and transport tasks with high speed and accuracy. The LCMR200 programmable workpiece transport solution works efficiently with Yamaha’s SCARA and Cartesian robots to speed up light manufacturing tasks and increase flexibility. Real-time tracking of all LCMR200 transport carriages increases traceability and facilitates system maintenance. The special horizontal and vertical circulation units enable the configuration of 2D and 3D transport networks in factories with very limited space.

Further information and the Yamaha Productronica press kit with the latest news and articles can be downloaded at https://smt.yamaha-motor-robotics.de/press-kits/.

About Yamaha Robotics SMT Section

The Yamaha Surface Mount Technology (SMT) Section, a subdivision of the Yamaha Motor Robotics Business Unit of Yamaha Motor Corporation, produces a comprehensive range of systems for high-speed inline electronics assembly. This 1 STOP SMART SOLUTION includes solder paste printers, pick and place machines, 3D solder paste inspection machines, 3D assembly inspection machines, flip-chip hybrid pick and place machines, dispensers, intelligent component storage and management software.

Bringing the Yamaha approach to electronics manufacturing, these systems emphasise intuitive operator guidance, efficient coordination between all in-line processes and modularity that enables users to meet the latest manufacturing requirements. The Group’s expertise in servo motor control and camera-based image processing systems ensures extreme precision at high speed.

The current product line includes the latest generation of YR machines with advanced automation features for programming, set-up and changeover, as well as the new YSUP management software with state-of-the-art graphics and integrated data analysis.

By combining expertise in design and engineering, manufacturing, sales and service, the Yamaha SMT Section ensures operational efficiency and easy support access for customers and partners. With regional offices in Japan, China, South East Asia, Europe and North America, the company offers a truly global presence.