Maximizes productivity and yield

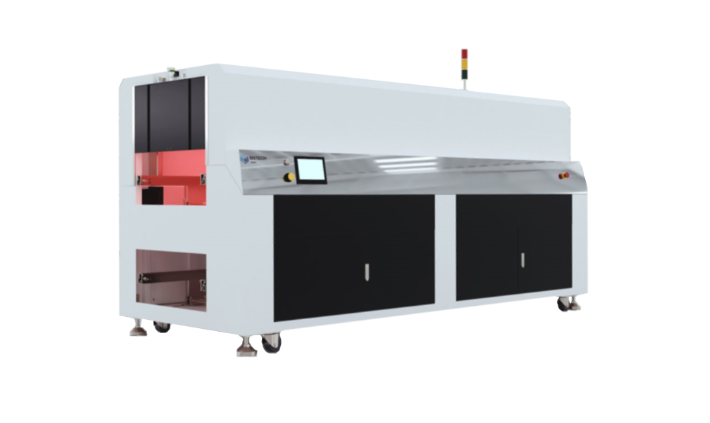

The IR curing oven for single-sided selective conformal coating of printed circuit boards (PCBs) maximizes productivity and yield, saves factory space and reduces PCB handling requirements.

The IR curing oven is available for integration into the modular Protection Concept line and can be configured for continuous and through-hole processing of PCBs in the IR curing process.

Technical details

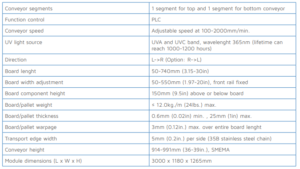

– Adjustable speed: The transmission system uses a

Adjustable speed from 100-2000 mm/min

– Electrical supply: Power supply: 3-phase, 380V

50/60Hz. Power consumption: Maximum 7 KVA.

– With adjustment option: electric and automatic width adjustment

. Automatic band width adjustment

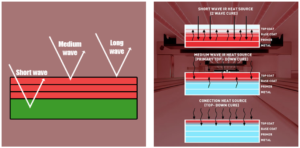

– Shortwave-Ir heat source: 2-wave cure

– Middle wave: Primary top-down cure

– Convection heat source: curing from top to bottom

– Coverage: The infrared radiation (IR) covers the

wavelength range above 800nm and is subdivided into

into the areas IR-A, IR-B and IR-C

Properties

PROCESS MONITORING

– During the whole protection process,

monitors the Programmed Logic Control

(PLC) module controls the loading and unloading process

Discharge process, the position of the circuit board

and the ventilation for possible

Solvent-based protection process.

SICHERHEIT

– Prevent safety interlocks

opening the door during operation.

– Pneumatic safety lock

MOISTURE CONTROL (optional)

– Air conditioning.humidity & TºC

Closed loop control