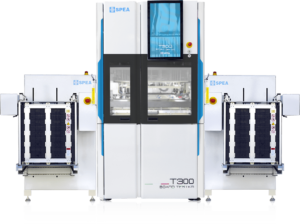

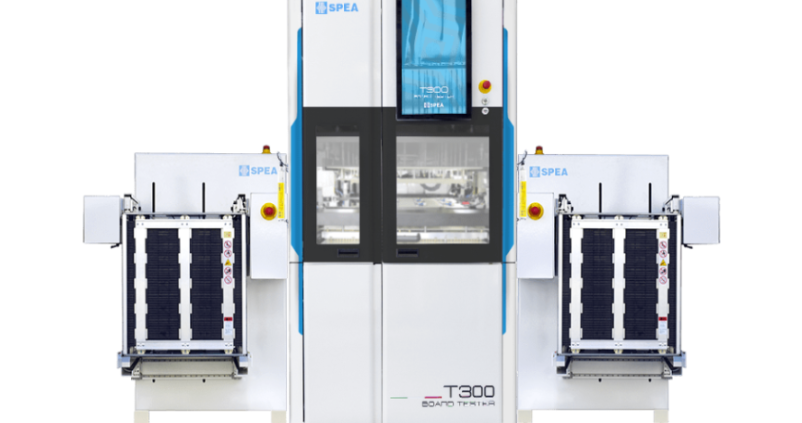

In-circuit tester with highest parallelism

32-fold parallel test

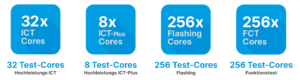

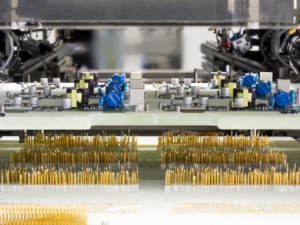

The SPEA T300 board tester has a unique tester architecture with up to 32 parallel incircuit test cores and additional capacity of 256 cores for flashing and functional testing. The asynchronous parallel architecture of the SPEA T300 allows testing and parallel flashing of up to 32 PCBAs (Printed Circuit Board Assembly).

The SPEA T300 Needlebed Tester offers SPEA’s unique ICT-Plus technology, which finds electronic faults that are not detected by conventional ICT tests.

Test and flash a variety of assemblies in parallel

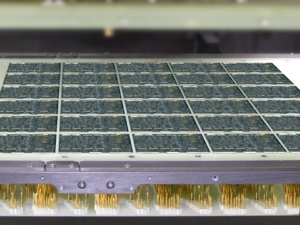

Many assemblies are manufactured in the panel, i.e. a few to a large number of assemblies are connected in the panel assembly to form a large printed circuit board. Each of these individual assemblies in turn contains a few to countless components and parts that must be tested and programmed.

SPEA’s new T300 board tester is specifically designed for user testing, or testing and programming many boards at once. It thus guarantees the highest throughput and the lowest testing and programming costs.

Programmable as single or dual test station

Programmable as single or dual test station

The SPEA T300 can be programmed as a single or dual test station.

In Single Test Site mode, a single board can be ICT and function tested and flashed.

Dual Test Side enables the simultaneous testing of two boards. This applies to ICT, flash programming and functional testing. To double the throughput, the tester can perform a split test. At Station 1, for example, an ICT is performed while at Station 2 either flashing or a functional test is performed simultaneously.

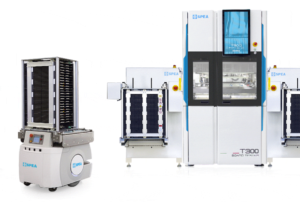

Operatorless testing

The SPEA T300 can be configured in several automated operating modes that operate unattended

- Inline loading – Inline unloading

- Loading from rack – inline unloading [1]

- Inline loading – unloading in rack [1] [2].

- Loading from rack – unloading into rack [1] [2].

[1] Option: Rack loading by robot

[2] Option: Pass – Fail – Sort

In-circuit tester – connected to the digital ecosystem

The SPEA T300 interacts with the Industrie 4.0 environment and digital ecosystem – in terms of information, notifications, programming commands and machine instructions.

The tester has sensors to detect and observe the environment, wear parts and moving parts, electrical and pneumatic power supplies, and internal and external power supplies. This enables him to:

- Support for predictive maintenance

- Error detection in advance, which would lead to malfunctions

- Estimation of wear and remaining service life of machine parts

The SPEA T300 is designed for continuous and intensive use even in harsh manufacturing environments. Easy to maintain – maintenance can be performed easily and quickly.

ATOS Leonardo 4 ICT is the T300 version of the ATOS system software developed by SPEA for its testers.

ATOS contains all the operating and programming functions needed for the tester. This makes you independent of the Windows® version and the configuration and performance of the system PC.

Leave a Reply

Want to join the discussion?Feel free to contribute!