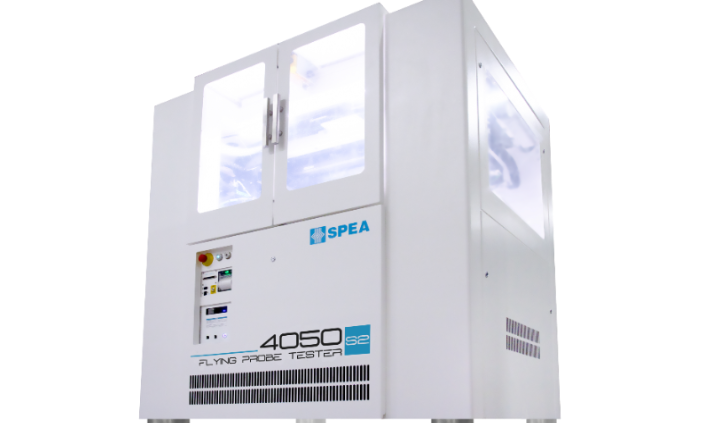

High productivity with maximum accuracy

Ideal for medium-volume production

Highlights

- High throughput

- High precision measurements

- Precise contacting of Micro-SMD

- No adapter costs

- Intuitive programming

- Highest error coverage

- Reduction of field returns

Multi-mode contacting

With the SPEA 4050, the 4 flying test heads on the top can be combined with additional test tools on the bottom. This increases test depth and throughput.

Each of the test probes can be used for an in-circuit test, a power-on test, as an analog sink/source, as a digital driver/sensor, for flashing via on-board programming, boundary scan and can be used as a prescaler.

The four needles from the top can be used for a standard flying probe test, while the lower platform can be used to accommodate additional fixed probes and adapters, various power supplies, digital I/O signals and support fingers. The 4 test needles from above can also be equipped with additional test tools.

Precise contacting of Micro-SMD

The miniaturization of components continues to advance – SPEA flying probe testers are equipped for this.

High-performance linear motors on all axes (X, Y, Z)

Precise contacting of Micro-SMD (008004)

Reliable testing of flexible/thin assemblies

Sticky boards for product start-up

Unique repeatability even with the smallest components over a long period of time

Ultra-Fast Soft-Touch technology: no damage caused by contacting, no stress and strain on the assembly and components

High precision measurements

- High-precision measurement performance and accuracy (0.1pF)

- Signal integrity

- No impairment of the measurement results or interference

- Immediate signal acquisition

High test speed

- High-performance linear motors on all axes (X, Y, Z)

- Maximum speed for all movements

- Maintenance-free: No impairment of accuracy due to wear and tear

- Extreme long-term stability and durability