|

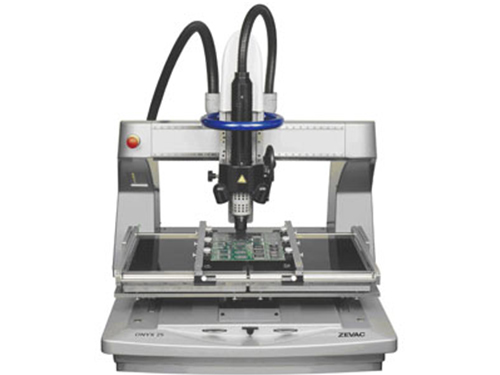

TECHNICAL DESIGNThe ONYX series, which has won design awards, combines a stable, innovative design in terms of both handling and construction. The ONYX 25 is designed to hold oversized PCBs safely and securely. CIRCUIT BOARD PREHEATERThe preheater has a standard output of 3500 W with a surface area of 300×300 mm, which can be increased to 7000 W with a surface area of 600×300 mm using an additional preheater module. With this level of performance, the necessary temperature profile for excellent lead-free soldering results can be defined, even for oversized PCBs. |

ONYX 25 MAIN FEATURES

|

| RESIDUAL SOLDER REMOVAL With the residual solder removal option, the residual solder is removed without contact after desoldering a component, without touching and thus damaging the surface of the PCB. The land surface is cleaned and prepared for soldering a new component after flux and solder paste have been applied.MOVABLE SOLDERING HEAD The combination of the open machine design with the movable soldering head allows free positioning in the X-axis without having to move the PCB. As the PCB remains in position, precise positioning of the component is guaranteed. For quick positioning above the work area.VISION-SYSTEM The advanced MFOV VISION system is part of the standard scope of delivery of all selective soldering devices in the ONYX series. It allows the complete view of components up to a size of 75 x 75 mm, but also smaller ones with an edge length of 0.3 mm.FORCE MEASUREMENT Force measurement is also standard on all selective soldering devices in the ONYX series. During placement, it protects sensitive components with a preselected contact force.REPEATABLE AND PRECISE AUTOMATION The VISUAL MACHINES™ machine software developed in-house is the basis for fast and flexible profile creation. The profiles stored in the library and the performance features of the machine guarantee repeatable, precise selective soldering results.LEAD-FREE APPLICATIONS All ONYX appliances from ZEVAC are supplied with a nitrogen connection as standard. This and the powerful top heating of 2000W and preheating of 3500W (7000W) provide the basis for reliable soldering results, even with lead-free operation. |

|