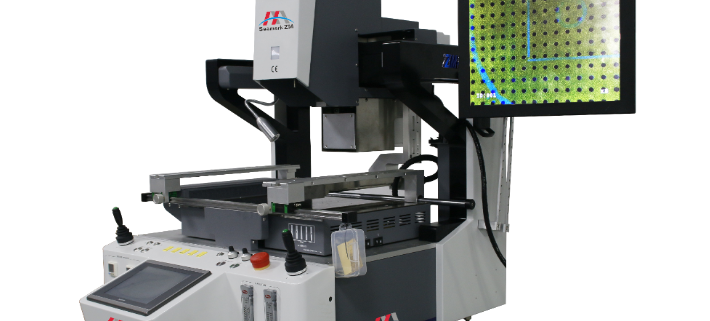

R7830A is an optical alignment automatic rework equipment. It also works as a laser BGA SMD rework station, multi-language menu interface, automatic feeding device, X/Y AXI machine, which can be controlled by joystick, fast and convenient operation, imported high-definition CCD (2 million pixels) optical alignment system, high-precision temperature control sensor system, precise temperature control.

As one of the most reliable manufacturers of BGA rework stations, Seamark ZM offers the best BGA rework station for motherboards with good quality.

Functions of the R7830A laser SMD rework station

– Automatic X/Y/Z axis shift

The upper temperature zone of the laser SMD rework station is controlled by the joystick control servo system, which can automatically move and align around the X/Y/Z axis at fast/slow speed.

– Vacuum adsorption and nitrogen protection

The upper heating head has a built-in vacuum suction nozzle for chip adsorption, an electrically controlled 360-degree rotation alignment, with vacuum monitoring and pressure protection device. The lower temperature zone of the laser SMD rework station has a large heating wire layout, moves symmetrically to the upper temperature zone and can be connected to nitrogen to prevent yellowing of the PCBA.

Features of the R7830A laser SMD rework station

– Multilingual menu navigation

– Automatic feed device

– X/Y axis can be controlled with joystick, operation is quick and convenient

– Imported high-resolution CCD (2m pixel) optical alignment system.

– High-precision system for measuring temperature control.

Specifications of ZM R7830A Laser SMD Rework Station

– Power supply: AC380V±10% 50/60HZ

– Power: 7.15KW(Max), Upper heater (1.45KW) Lower heater (1.2KW), IR preheater (4KW), Other (0.5KW)

– PCB size: 565*467mm(Max); 6*6mm(Min)

– BGA chip size: 80*80mm(Max); 2*2mm(Min)

– IR heater size: 500*380mm

– Motion control: X/Y/Z

– Temperature sensor: 5 pcs.

– Operation: 8″ HD touch panel

– Steuerungssystem: Panasonic PLC + Temperaturregelungsmodul

– Display system: 15″ HD industrial display (1080P 16:9)

– Alignment system: 2 million pixel HD digital imaging system, automatic optical zoom with laser red dot display

– Vakuumadsorption: Automatisch

– Alignment accuracy: ±0.01mm

– Temperature control: thermocouple type K with closed control loop and an accuracy of up to ±1℃

– Feeding device: Yes

– Positionierung: V-Nut mit Universalbefestigung

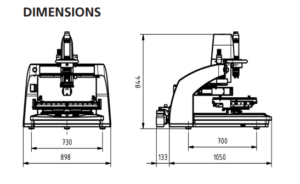

– Dimensions: L810*W1100*H960mm

– Weight: 151KG