Calibration + electrical test + optical test + mechanical test.

Up to 8 freely movable test heads. All in one system.

Highlights

ATE – Automatic test system, fully programmable and applicable for different products

Calibration, test, inspection and flashing of micro-optics, MEMS, sensor technology, microelectronics and micromechanics

Fully integrated and synchronised electrical, optical and mechanical stimulation via freely movable actuators, up to 4 above and 4 below

Configurable tools and instruments (top and bottom)

Configured as an inline system

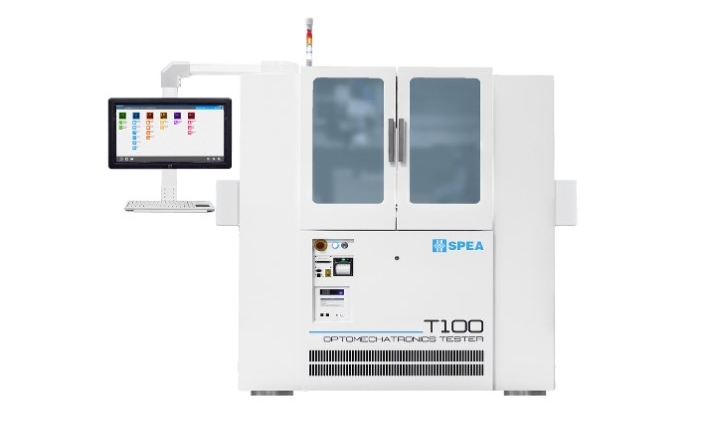

The very first optomechatronics tester

on a Flying Probe basis

The T100 is a newly developed system from SPEA for testing and calibrating electronic devices and assemblies of all kinds that contain electronic, optical and mechanical functions. This is done by using the latest technologies from the fields of optics, MEMS, sensors, microelectronics and micromechanics.

The T100 can be equipped with different tools and actuators that perform calibrations, electrical, mechanical and optical tests.

And all this with just one system – no additional test systems necessary.

The new SPEA T100 offers the optimal and universally applicable solution for a wide variety of products and for production with many variants.

Fully configurable

The SPEA T100 can be equipped with up to 4 freely movable test heads (XY) each on the top and the bottom side, on which various actuators can be mounted, such as:

- Pressure actuators for testing, calibrating and measuring all pressure-sensitive objects (keyboards, push buttons, 3D displays, flexible devices)

- Z-actuators for moving optical and electrical tools on the Z-axis

- Laser module for testing, calibrating and measuring mechanical dimensions, deformations and planarities

- Exposure meter for calibrating and measuring a wide variety of light sources such as LEDs, LIDAR systems and displays

- Light source for testing, calibrating and measuring light sensors or LIDAR sensors

- Cameras to check for presence, alignment, shape of components and parts, hole dimensions, scratches or dust on the product surface.

- Sound module for testing, calibrating and measuring sound emission devices (buzzer, loudspeaker)

- Motorised screwdriver for assembling, screwing and calibrating mechanical or electromechanical devices

Testperformance

- Electrical: Parametric Test, Performance Test, Functional Test, Waveform Capture, RF Test, 5G Test,Flashing

- Dimensional: Homogeneity test, correct position test, correct dimensions test, 3D scan test (shape and profile).

- Mechanical: Pressure test, movement test (travel test), grip test (swipe test)

- Optical: Checking measured values, AOI, light test, laser test, character recognition, hole measurement, surface test, solder paste test

- Thermal: temperature recording, temperature control

The tester can be configured as an inline version. The assemblies are identified using 2D barcode or RFID readers.

On some models of the SPEA T100, a movable platform can be installed in the lower test area, which can be equipped with additional actuators and other test tools.

The SPEA T100 uses the ATOS system software, which offers automatic test generation and the highest test coverage.