This unit is named after the SPI/AOI machine in order to

inspect N/G panels in the line. The operator can be informed after NG

Visually inspect boards stacked in the rack on the 2nd layer of the conveyor belt while the good boards pass through to the downstream machine without interruption.

Standard features

• NG/OK panels can be intelligently separated in any position on the conveyor belt

Conveyor belt

• FIFO/LIFO, BY-PASS, NG Reject function selectable

• Mitsubishi PLC program control

• Selectable pitch settings

• Servo motor system to improve work efficiency

• Built-in rack structure

• Encapsulated CE construction to improve the safety level

• Conveyor belt and shelf adjustment through motorized

• Separately driven buffer conveyors

• Storage capacity for 25 PCBs

• Use the friendly touchscreen panel

• SMEMA-compatible

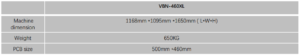

Technical data

Optional:

• Outlet conveyor

• Automatic adjustment of the conveyor belt width via software

• Additional capacity for PCB boards