The single magazine storage unit is designed for

loading, unloading, buffering (FIFO, LIFO) of printed circuit boards, bypass function and NG boards Storage

functions.

Standard features

• Available operating mode Loader, unloader, buffering

(FIFO,LIFO),Bypass

• NG plates storage capacity: 50PCS in NG rejection mode

• Mitsubishi PLC program control + touchscreen control panel

• Handle with dual function (driven by stepper motor)

• Selectable pitch settings from 10 mm to 80 mm;

• Automatic cocking of the magazine due to the high-quality air

cylinder

• Lighthouse display for the operating status of the machine.

• PLC control + touchscreen operation

• The magazine feed and pull-out are automatically controlled by an

motor on the platform.

• SMEMA-compatible

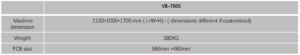

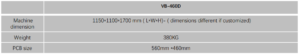

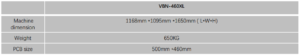

Technical data