Laser Depaneling machine: Best cutting quality and outstanding performance

• PCB milling and cutting with laser

Source

• Support for hybrid printed circuit boards (FPCB,

Rigid-Flex PCB)

• Minimisation of particles through non-contact

Cutting

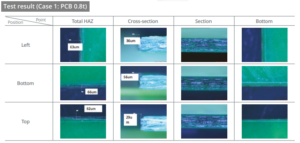

• High cutting quality compared to contact

Router (100um –> under 30 um)

• Supports the cutting of printed circuit boards with complex shapes

• Stress-free, no mould cutting, no tooling costs

Eigenschaften

• Use of different laser sources such as UV, green, IR, etc.

• Cutting of materials: FR4, FPCBs, Kapton, etc.

• Thickness up to 1.2 mm in the case of FR4 PCB

• Pin table, production device

• Full-cut process, support for highly populated

PCB board

• Best cutting quality (minimisation of charring)

• Clean particle and smoke removal process

Advantages

• Simple setup of BDS (Beam Delivery System)

• Automated management of laser power

• Application of the optimised optical system

• Incredible cost efficiency with 2 tables

• Fully graphical interface and simple programming

• Real-time monitoring of the most important processes

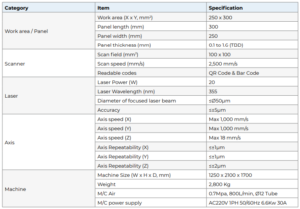

Parameters

Options

• Hybrid cutting with drill and laser

• AL. PCB, ceramic PCB, etc.

• In-line laser milling

• Recognising the fingerprint

Technical details