Shuttle Conveyor / Traverser is used to

change the flow of printed circuit boards to different channels

in a production line.

It is designed to transport the PCBs to the next process. The conveyor belt can collect PCBs from two lines to one line and distribute them from one line to two lines.

Standard features

• Mitsubishi PLC program control

• Bypass mode, inspection

• Width adjustment of the conveyor belt with hand crank

• Center PCB stop position

• Heavy base construction to prevent slipping

• The conveyor motor is operated with a stepper motor

• PCB flow direction can be adjusted

• Fixed rail: Front rail

• Conveyor concept: ESD flat belt

• Cycle time: Dependent on the travel distance

• Setting the shuttle speed via software

• SMEMA-compatible

Optional:

• Motorized width adjustment

• R485 Communication protocol

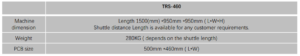

Technical data

Transfer heights: 900mm+/-50mm

Transmission direction: From left to right

Operating side: front of the machine

Fixed rail: front of the machine

Interface: SMEMA

Conveyor belts: ESD flat belts

PCB edge support: 3mm

Permissible component spacing: 80mm top +30mm bottom

PCB thickness: 0.5mm-2.5mm

PCB transmission mode: 2 in 2 out; 1 in 2 out ; 2 in 1 out

Transfer trolley number: Standard single trolley

Width of the conveyor: Min. 50mm to max.460mm

NG Reject function: OPTIONAL

Inspection interval: Setting by software (optional)

Safety: CE certificates

Control system: PLC

Voltage:220V/ 110V , single-phase, phase, 50-60Hz