This unit is specially designed for unloading printed circuit boards from the

Wave soldering machine.

The transfer heights are adjustable, for every type of

wave solder on the market.

Standard features

• Mitsubishi PLC program control

• Continuous queue, the printed circuit boards into the wave soldering machine machine.

• Width adjustment of the conveyor belt with hand crank

• PCB transmission angle is adjustable

• Heavy base construction to prevent slipping

• The conveyor motor is operated with a stepper motor

• Conveyor belt transfer with ESD flat belts

• Conveyor belt transfer by means of a chain

• PCB flow direction can be adjusted

• SMEMA-compatible

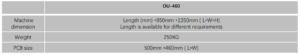

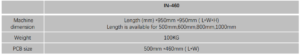

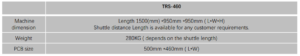

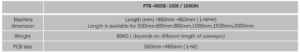

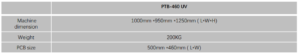

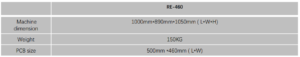

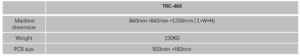

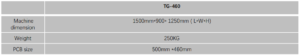

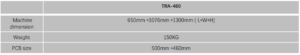

Technical data