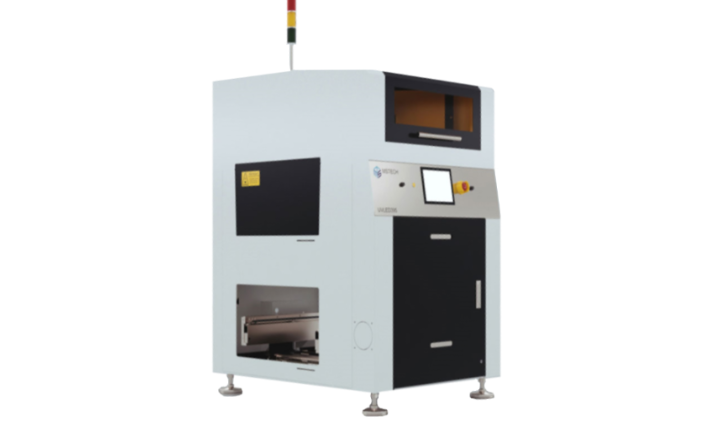

Advanced ultraviolet curing system for conformal coatings

The high-power area light source is integrated into our fully integrated modular system with a simple, flexible control system, conveyor belts and a range of options and accessories to meet all requirements.

The UV radiation source has the best efficiency in the world using high-performance LEDs. The frequency is tuned to 395nm.

Integrated, programmable forced air cooling over the entire surface of 500 mm x 400 mm.

The small footprint is prepared for easy integration into any automated line, full SMEMA compatibility and Industry 4.0 data export functions offer exceptional capabilities and traceability.

Technical details

– Wavelength: 395nm. Options: 365nm, 385nm, 405nm

Options: 365nm, 385nm, 405nm

• Electrical power: 1800w

• Curing range: 500x400mm (curing option

area 800x500mm)

• Curing side: Top side (top and bottom option)

in the upper conveyor or return conveyor

• Best curing distance: 50-150mm

• Power intensity: 1000mW/cm2 (at 15cm

working distance)

• Cooling method: Fan cooling

• Humidity control: Air conditioning (humidity

& TºC control in closed control loop) (option)

• No warm-up required after switching on: Immediately

Switch on/off. It immediately reaches the maximum light

light intensity immediately, whereby the

Service life

Properties

Flexibility in dimensions

• Support for PCBS boards and pallets

• From small: 50 mm x 50 mm to

full size: 710 mm x 550 mm

Board details

• Board with setting: 50-550

mm (1.97-20 in.), front rail fixed

• Component height of the panel: 150 mm

(9.5 in.) above or below the plate

• Board/pallet weight: ≤ 12.0 kg/m

(24 lbs.) max.

• Thickness of the board/pallet: 0.6 mm

(0.02 inch) min., 25 mm (1 inch) max.

No infrared radiation

Cold light source, suitable for curing

All types of heat-sensitive materials

Lamp control

• Panel display: LCD operation

• Power: 0-100% adjustable

• Monitoring the temperature

• Power supply: 110/220VAC

50/60HZ

Advantages

Compared to other curing systems

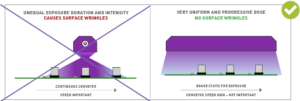

• Simple UV dose production

Concept simple

• Process stability and repeatability are

guaranteed with minimal parameters

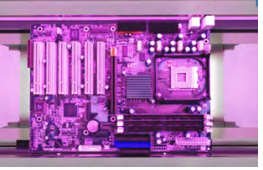

• Full-surface covering of the panel in a single operation

-Uniform coverage: no creases, no wrinkles, no

Shadow

• No additional variables, no

Reflector, longer lamp life

UV-LED irradiation

• UV-LED irradiation head with

powerful UV LEDs – covers the entire surface of the

Circuit board

Hardness range

• Efficient curing area of 500×400

mm at a distance of 10 to 400 mm

Focused spectrum wavelength 395nm

• All new LED coating materials

have specific wavelengths for

curing

• Other wavelengths are just wasted

energy

LED advantages

• Very fast: 100% curing <2 sec.

• Low process temperatures

• Low power consumption

• Low infrastructure requirements

• Small footprint

• Very simple and stable configuration

• Very high component spacing

<400 mm