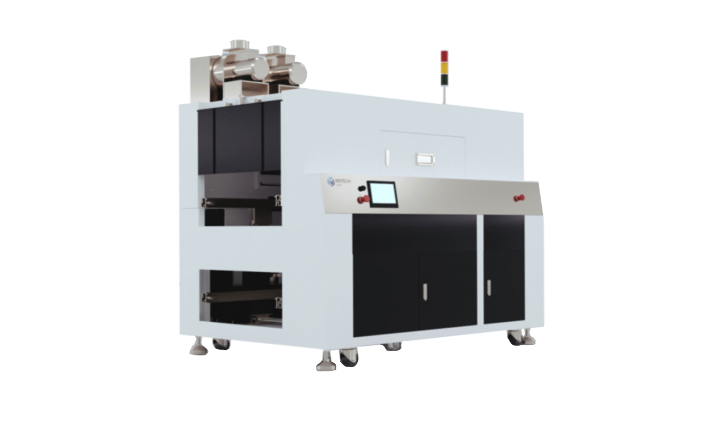

Inline UV Mercury oven

The UV mercury oven for single-sided selective conformal coating of printed circuit boards (PCBs) maximizes productivity and yield, saves factory space and reduces PCB handling requirements.

The UV mercury oven is available for integration into the modular Protection Concept line and can be configured for the processing of printed circuit boards in a continuous process using the UV mercury curing method.

Technische Einzelheiten

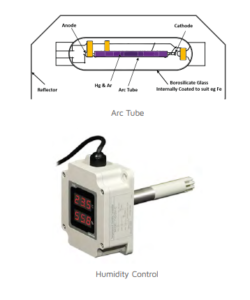

• HG lamps: HG high-pressure lamps are

required for industrial curing. These work with up to

20 bar due to gas expansion

• Arc tube: An electric arc is ignited via a

quartz glass arc tube containing mercury and

argon. The light has bandwidths with sharp

concentrations at certain frequencies

• Mercury vapor lamp: gas discharge lamp

• Stops the system: The appliance is equipped with a

differential pressure switch that stops the system immediately

if the ventilation falls below

the prescribed values.

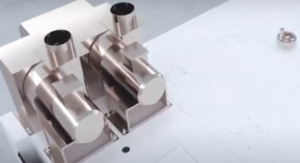

• Width adjustment: electric and automatic

width adjustment

• Humidity control (optional): Air conditioner

(humidity and TºC control in a closed circuit)

Functions

Process monitoring

During the entire protection process

monitors the Programmed Logic

controller (PLC) controls the charging and

the loading and unloading process,

position of the circuit board and exhaust air

Ventilation for possible solvent-based protection processes.

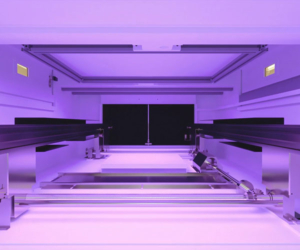

Ventilation concept

Unique ventilation design: Enables

cooler operation of the oven and extends

the service life of the electronic components.

50% Of directed light

The reflector supplies over 50% of the

directed light. The efficiency is

more and more over the course of time:

• Ozone pollution

• UV surface breakdown

• Temperature on airborne

Pollutants

Specifications for inline modules

• Control system: Instrument control

• The service life of the UV lamp can reach 1000-1200 hours

• Focus Design Import high light reflector lampshade

• Independent cooling area ensures low

Temperature when PCB comes out

• The transmission system uses an adjustable speed of

100-2000mm/min

Details on hardness

• The luminosity of the lamp is proportional to the vapor

Temperature

• Electron arc temperatures with pressure increase

during the warm-up phase

• Ballast resistors required to prevent explosions

• High intensity light – cannot be low Light off

a single area must be distributed