The vacuum loader is used to load PCBs for

SMT production lines. The top PCB is lifted from the stack and lowered onto a belt segment. The stack of printed circuit boards goes

manually into the machine and the individual circuit boards are transferred to the downstream machine on a transfer belt.

Standard features

• Screen touch panel control + Mitsubishi PLC

• Bare boards charging mode and by-pass mode selectable

• Complete upper safety viewing window with locking mechanism

• The adjustable positions of the vacuum nozzles offer a better way to hold the different PCB sizes

• PCB-Counter

• Automatic positioning of the shuttle distance and precise release of the PCB on the conveyor rail.

• Improved suction stability through the use of a robust system.

• Pre-warning limit alarm for empty stack

• The rail width is adjusted with a hand crank

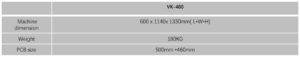

Technische Daten

Transfer heights: 900mm+/-50mm

Transfer direction: Left to right

PCB duty cycle time: 3s-7s ( adjustable)

Operating side: front of the machine

Fixed rail: front of the machine

Interface: SMEMA

Conveyor belts: ESD flat belts

PCB edge support: 4mm

Permissible component spacing: Top 20mm, bottom 20mm

PCB thickness available: 0.6mm +

PCB weights available: 1KG

PCB stacking heights: 240mm / fix

PCB capacity: 400PCS (0.6mm thick board)

Air supply:4-6 bar

Safety: CE certificates

Control system: PLC

Voltage:220V/ 110V , single-phase, phase, 50-60Hz