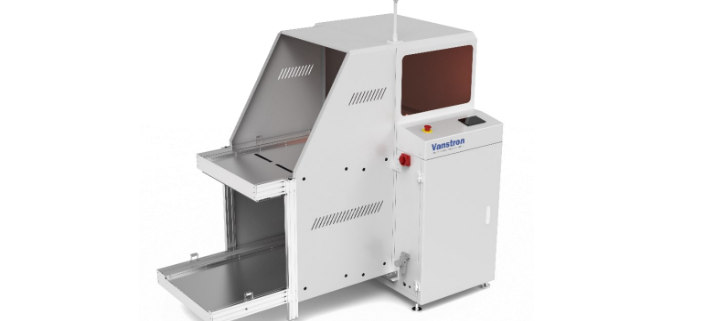

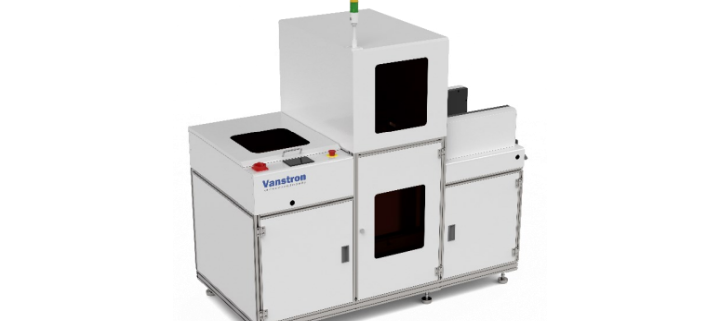

The automatic magazine loader is designed for

loading of PCBs into the SMT line.

This system is designed with the “L” type to

save the length of the line. To save space, the

magazine transport section for feeding the magazine beaters can be positioned either at the front, rear or back, depending on the customer’s requirements.

Standard features

• Mitsubishi PLC program control

• Selectable pitch settings

• Lighthouse display for the operating status of the machine.

• Flexible platform for holding standard magazines

• Interchangeable magazine from the back of the magazine

• Stepper-motorized slider to improve the working

Stability

• The position of the ejector can be centered for the panels

• Use the user-friendly touchscreen control panel

• The magazine feed and pull-out are automatically controlled by an

motor on the platform.

• SMEMA-compatible

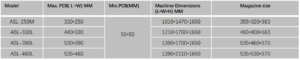

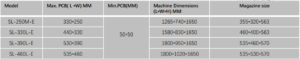

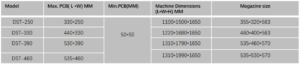

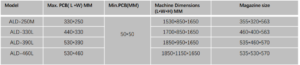

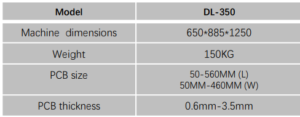

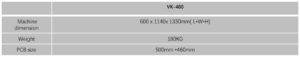

Technical data