This unit is for loading the circuit boards

on the SMT line. Unique separating cams

take a PCB from the underside of the stacked PCBs and gently lower it onto the ESD strips

for transfer to the downstream machine.

Standard features

• Mitsubishi PLC program control

• Bypass and destacker mode can be selected in the software Software

• Shortest charging cycle time for PCB

• 0.6 mm thick PCBs can be processed

• Uninterrupted PCB charge

• Pre-signal alarm for PCB understack heights

• Using the user-friendly touchscreen panel

• Smooth and parallel width adjustment by crank wheel (optional: motorized).

• Locking system for all open doors to improve the

Operational safety

• SMEMA-compatible

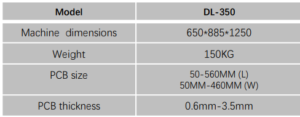

Technical data

Optional:

• Motorized adjustment

• Automatic adjustment

• Extension for convenient stack loading

• Overhanging input and output conveyor belt

• Ethernet communication with CMS software