Vacuum loaders for SMT production lines – Automatic, safe, and efficient PCB loading

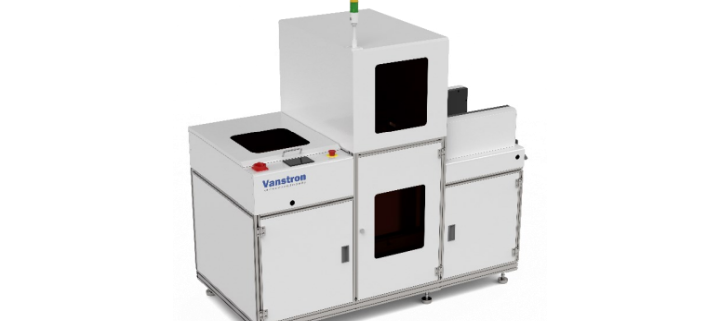

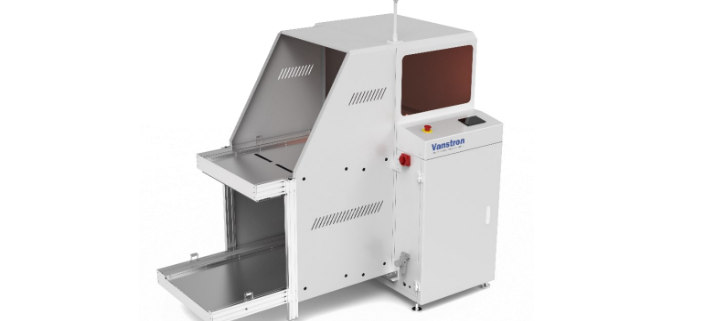

The vacuum loader is an automatic feeding system for SMT production lines that enables precise and safe loading of PCB stacks.

The top circuit board is lifted from the stack using a robust vacuum system and lowered onto a conveyor belt, which transfers the board to the downstream station.

This minimizes manual effort, increases productivity, and optimizes process reliability in circuit board production.

Efficient loading with precise control

The system is equipped with a touchscreen control and a Mitsubishi PLC, which ensure stable and precise process control.

The operator can choose between bare board loading mode and bypass mode—ideal for flexible production requirements.

All parameters, such as suction height, positioning, and conveyor speed, can be easily set via the control panel, enabling quick changeovers and high user-friendliness.

Stable vacuum system for different PCB sizes

The adjustable positions of the vacuum nozzles enable the safe handling of different PCB sizes and thicknesses.

The robust suction system offers improved stability and ensures reliable lifting even with light or thin circuit boards.

A warning limit alarm informs the operator in good time when a stack is empty, thus avoiding production interruptions.

High process reliability and user-friendliness

An upper safety viewing window with a lock protects the operator while providing a clear view of the work area.

Automatic positioning of the shuttle distance ensures precise release of the PCBs on the conveyor rail, effectively preventing damage.

An integrated PCB counter monitors processing in real time and facilitates production control.

Compact design and easy integration

With its compact design and standardized SMEMA interface, the vacuum loader can be easily integrated into existing SMT lines.

The rail width is conveniently adjusted using a hand crank, allowing the system to be quickly converted to different PCB formats.

All components are ESD-safe to protect sensitive assemblies from electrostatic discharge.

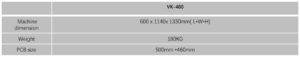

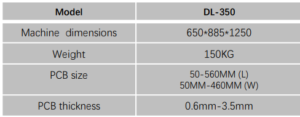

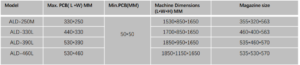

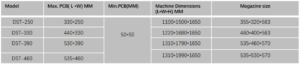

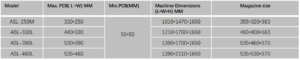

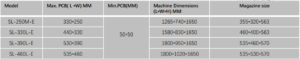

Technical data

- Transfer height: 900 mm ±50 mm

- Transmission direction: From left to right

- PCB cycle time: 3–7 seconds (adjustable)

- Operating side: front of the machine

- Fixed splint: Front

- Interface: SMEMA-compatible

- Conveyor belts: ESD flat belts

- PCB edge support: 4 mm

- Component spacing: 20 mm at the top, 20 mm at the bottom

- Circuit board thickness: ≥ 0.6 mm

- Max. PCB weight: 1 kg

- Stack height: 240 mm (fixed)

- Capacity: Up to 400 PCBs (0.6 mm thick)

- Air supply: 4–6 bar

- Voltage: 220V / 110V, single-phase, 50–60Hz

- Control: Mitsubishi PLC

- Safety: CE certified

Standard features at a glance

- Touch panel control with Mitsubishi PLC

- Two operating modes: Bare-Board & Bypass

- Vacuum nozzles with variable positioning

- Improved intake stability thanks to robust system

- Automatic positioning & precise PCB release

- Early warning system for empty stack

- Safety-locked viewing window

- Manual rail width adjustment

The vacuum loader for SMT lines is the perfect solution for precise, clean, and safe PCB handling—ideal for modern electronics manufacturing that prioritizes process automation and productivity.

To the other products ->