This unit is responsible for unloading the

PCBs from the production line.

Standard features

• Mitsubishi PLC program control

• Bypass and destacker mode can be selected in the software Software

• Shortest charging cycle time for PCB

• Pre-signal alarm for PCB understack heights

• Using the user-friendly touchscreen panel

• Smooth and parallel width adjustment by crank wheel (optional: motorized).

• Locking system for all open doors to improve the

Operational safety

• SMEMA-compatible

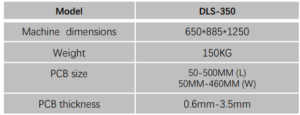

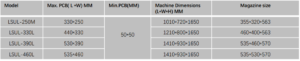

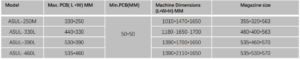

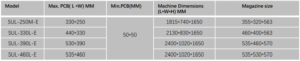

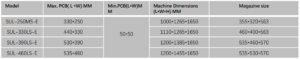

Technical data

Optional:

• Motorized adjustment

• Automatic adjustment

• Extension for convenient stack loading

• Overhanging input and output conveyor belt