Micro Denier Wiper

Micro Denier Wiper

Micro-denier wipes provide the highest level of contamination control without the potential recontamination of traditional cleanroom detergents. They are woven or knitted from super-soft, continuous-fiber reinforced micro-denier polyester and nylon with increased absorbency and are ideal for cleaning scratch-sensitive surfaces, while the sealed edges ensure low fiber shedding.

• Washed with 18MΩ de-ionized water and packaged in a class 10 clean room

• Good chemical resistance

• Edge processing: Laser-cut and sealed

Polyester Wiper

Polyester Wiper

Knitted polyester fabrics are made of 100% synthetic polyester with interlocking filaments.

They are the primary wipes used in class 1′ to 1,000 (ISO 4-ISO 6) cleanrooms. It offers various options depending on the knitting pattern and edge treatment.

• Offers various edge treatments

• Double-knit, low-fiber

• Superior strength enables rigorous wiping

• Washed with 18MΩ de-ionized water and packaged in a class 10 clean room (ISO 4)

Non-Woven Wiper

Non-Woven Wiper

Strong and excellent chemical resistance due to the high absorption of cellulose and the high abrasion resistance of polyester.

• Fabric produced using a newly developed process to obtain the cleanest wipes

• Shaped with water jets that clean the fibers

• No binders or chemical additives

• Low particle generation

• Excellent absorption capacity

Hand cleaner

Hand cleaner ESD dust removal pad

ESD dust removal pad Gel Stick

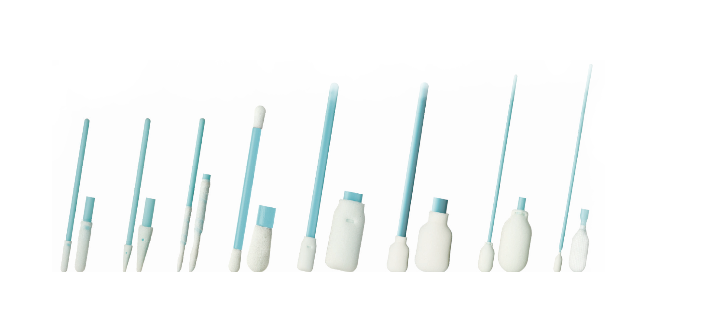

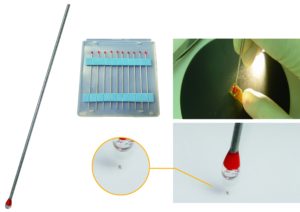

Gel Stick PU foam swab

PU foam swab Polyester foam swabs

Polyester foam swabs ESD PE solvent bottle with pump

ESD PE solvent bottle with pump Ultrasonic Cleaner

Ultrasonic Cleaner