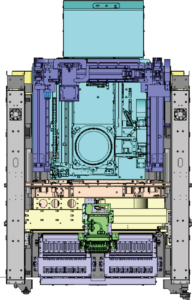

Overview

• Hybrid assembly

Realize mixed assembly of semiconductors and SMDs

• High-speed and high-precision assembly

±15μm(Cpk≧1.0) CPH10.800(if the chip is supplied from the wafer) Note: under optimum conditions

• Improved component feed

Intelligent feed

• Handling large PCBs

L330 x W250mm

Mixed assembly of semiconductors and SMD

It is capable of various types of production process and YRH10 realizes SMT for semiconductor, SMD in one unit. Inspection after installation is part of the standard equipment.

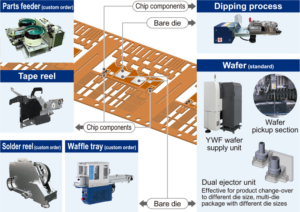

Supply patterns

Pin transfer of adhesives

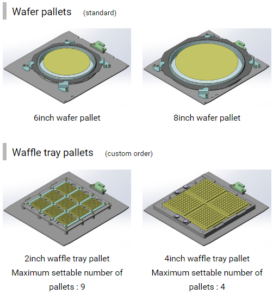

Pallet types

High-speed and high-precision assembly

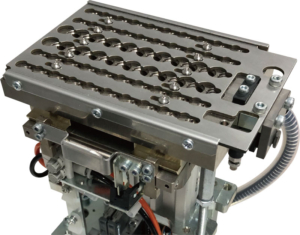

The placer with 10 nozzles on the assembly head enables high productivity with high assembly accuracy.

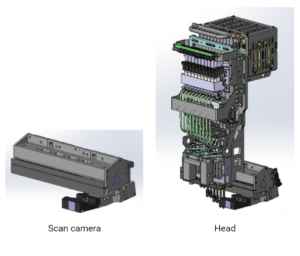

Inline head with a scan camera

The flexible high-speed head covers everything from very small to medium-sized, irregularly shaped components. By using a scan camera, the working path from recording to assembly is the shortest, resulting in high productivity.

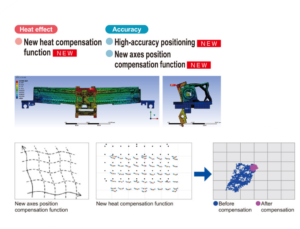

Multiple Accuracy Compensation System (MACS)

The compensation system developed by Yamaha enables a high mounting accuracy of ±15μm (μ+3σ).

Available for intelligent feeding and various options

Available for intelligent feeders that improve the pick-up accuracy for reel components.

The combination with the Multiple Accuracy Compensation System MACS enables high-precision component mounting and assembly.

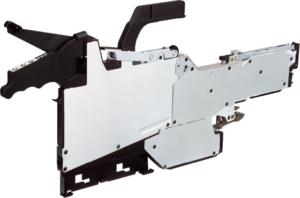

ZS feeder

Available for electrical intelligent feeders that are also used for machines. Compact and lightweight feeders improve processability and reduce the strain on operators.

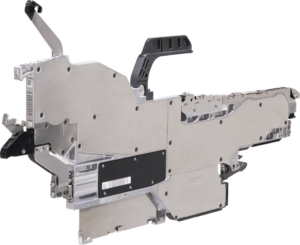

Auto Loading Feeder

An auto loading feeder, for which two rollers can be set in advance, is also supported. This type eliminates the need for splicing and the supply can be varied over time. This significantly reduces the reduction in working speed due to missing components.

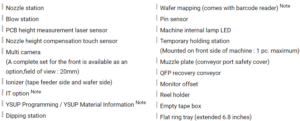

Various options

Available for nozzle stations, blow-out stations and other options for various applications.

Nozzle station

Automatic replacement of special and spare nozzles.

Options

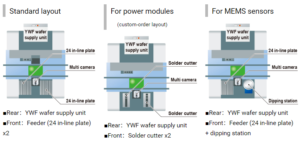

Can be used for various production processes

Customizable for different production layouts based on product types.

The highly productive flexible pick and place machine helps to realize highly efficient production processes.