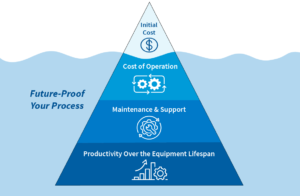

Lower costs. Everybody wants that. There are many ways to achieve this. On the surface, a low purchase price is the obvious solution. But is this the best way to control costs? Smart buyers look at total cost of ownership to maximise their return on investment. You know that acquisition costs are only one part of the purchase equation.

A look below the surface

When calculating the total cost of ownership, not only the initial cost should be considered, but also the cost of operation, maintenance and support, as well as the potential productivity over the lifetime of the device. Other factors to consider are the cost of consumables and possible downtime. Expertly designed equipment offers total cost of ownership benefits for any application – from long-term, continuous manufacturing in automotive and medical applications to fast-turnaround applications for mobile devices and PCBAs. Robust, upgradable equipment offers long-term reliability with opportunities for reuse, redeployment and adaptation to changing application requirements. Ultimately, these factors give you complete control over the improvement in total cost of ownership, year after year.

Let us consider an example:

You have just integrated several new dosing platforms into your production line. The purchase was mainly based on the acquisition price. Although you have secured most of the required functionality, some important functions still do not work after installation. But you are reassured by your supplier’s offer to provide five full-time technicians on site to keep your process efficient. Things seem to be going well and you are reaching your production targets.

-But what happens when:

-Your warranty or service contract is expiring.

-The dedicated technicians on site leave you.

-You have long downtimes due to application problems.

-Frequent maintenance or spare parts are required.

-Rework is increasing.

-Your application requirements change in the second or third year of production.

Focus on total cost of ownership to future-proof your process

Go beyond the purchase price. By evaluating all total cost of ownership factors during the procurement process, you can avoid unplanned costs and achieve continuous production success. Nordson offers several dispensing solutions to lower your total cost of ownership, as well as award-winning global application support in your region. Since 1954, Nordson has delivered high-quality technology solutions to help customers succeed worldwide.

Spotlight: The Forte Series

The Forte® series, in conjunction with the award-winning IntelliJet® jetting system, offers best-in-class cost reduction and productivity features, including:

-Improved cost of ownership, equivalent or better accuracy and 20-50% higher productivity over the best-selling Spectrum® ll.

-Astonishing speed for point-to-point movements – matches our most advanced fluid dispensing system at 1.5G.

-Patented* real-time correction for skewed parts with Forte MAX double valve to increase yield and throughput.

-Lower maintenance and operator intervention with a standard integrated dual valve service station, patented closed loop process control and nozzle cleaning rail.

-A space-saving footprint for maximum efficiency in production.

-Flexible application support: FPCBA, PCBA, EMA, MEMS, underfill, precision coating and encapsulation.